ELEC 242 Lab

Experiment 10.1

Building the Motor Controller

New Components

- 4013 CMOS Flip-Flop

- Capacitor: 100

F

F

- Resistors: 3.3 k

,

33 k

,

33 k ,

100 k

,

100 k ,

2-1 M

,

2-1 M

- Potentiometers: 1 k

, 10 k

, 10 k

The "only" thing we have to do in this lab is

to control the receiver motor

to synchronize it with another

camera, rather than driving it directly from a voltage source.

Unfortunately, there are several new components we need to do this,

so we have a bit of wiring to do before we can proceed.

The synchronization technique we will use is called a

Phase Locked Loop

(PLL).

The name pretty much describes how it works:

It is a closed loop feedback system where the frequency of one

signal (the sync pulses from the receiver disk) is controlled

(by varying the speed of the receiver motor) so that it is

"locked" in phase with another signal

(the sync pulses from the transmitter disk).

There are three basic components in this motor control circuit:

the phase detector, the loop filter, and the motor amplifier.

Here's how they fit together:

Since you are going to connect your receiver to another camera,

and since there is only one camera/receiver per lab group,

you will have to find another group to act as your transmitting

station when you are ready to receive.

Since we have both 6 ft. and 25 ft cables, you have considerable

freedom in choosing a partner for this lab.

Part 1: Preliminary Test

| |

|

|

Step 1: |

|

Verify that your system still works by repeating steps

1 and 2 of

Experiment 9.2.

|

Part 2: Motor Driver

The first step is to connect the motor to the motor

amplifier instead of the 0-6 V power supply.

This is what we'll have when we're finished:

If you have kept your circuitly from Labs

7 and 8, you have

most of this already: It's just the summing amplifier with

a new feedback resistor and one of the inputs eliminated.

If you have kept your circuitly from Labs

7 and 8, you have

most of this already: It's just the summing amplifier with

a new feedback resistor and one of the inputs eliminated.

| |

|

|

Step 1: |

|

Disconnect the motor (pin 52 of the interface board socket strip)

from the 0-6 V power supply (pin 30) and connect it to the output

of the motor amplifier.

|

Step 2: |

|

If you have kept your summing amplifier from Labs 8 and 9,

modify it by replacing the feedback resistor  with a

100 k

with a

100 k resistor and removing the 330 k

resistor and removing the 330 k resistor.

If not, replace it with the following circuit

resistor.

If not, replace it with the following circuit

|

Step 3: |

|

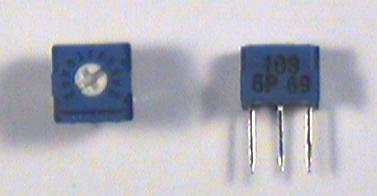

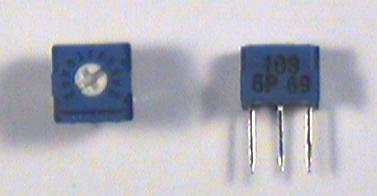

Select a 1k potentiometer from your parts kit.

It will have three short wires sticking out the bottom in a

triangular pattern.

The center terminal is the slider contact and the two outer terminals

are the fixed contacts.

potentiometer from your parts kit.

It will have three short wires sticking out the bottom in a

triangular pattern.

The center terminal is the slider contact and the two outer terminals

are the fixed contacts.

Note

Figuring out the value of a pot can be tricky.

Some pots are labeled directly with the value

(e.g. "100" or "10K").

Others are labeled using the same code as for fixed resistors,

execpt that numbers, rather than colors, are used.

For example, a 1k resistor would have the bands

brown-black-red. The values of these colors are 1, 0, and 2,

so a 1k

resistor would have the bands

brown-black-red. The values of these colors are 1, 0, and 2,

so a 1k pot would have the label "102"

pot would have the label "102"

|

|

Step 4: |

|

We will use this potentiometer, instead of the control on the

power supply, to set the speed of the motor.

Since the summing amplifier is inverting, we need something we can

adjust to about -4 V.

Wire the following adjustable voltage divider near to the summing

amplifier.

|

Step 5: |

|

Connect  from the speed control to the appropriate input of

the summing amplifier.

Make sure nothing is connected to

from the speed control to the appropriate input of

the summing amplifier.

Make sure nothing is connected to  (it was

(it was  in Labs

8 and 9 and was connected to D/A channel 1).

Your motor amplifier circuit should now look like this:

in Labs

8 and 9 and was connected to D/A channel 1).

Your motor amplifier circuit should now look like this:

|

Part 3: 15 Volt Sync Pulse

The phase detector is a CMOS flip-flop

with logic levels of

+15 V and ground.

Fortunately the sync circuit we already have produces a 15 V

pulse as well as a 5 V pulse.

All we need to do is give it a name.

Time to test what we've done so far.

| |

|

|

Step 1: |

|

Turn on the power supply.

The disk should be

rotating in a clockwise direction as

seen from the front of the camera.

|

Step 2: |

|

Connect  to Channel 1 of the scope.

to Channel 1 of the scope.

|

Step 3: |

|

Adjust the

speed control

potentiometer until the signal has

a frequency of exactly 30 Hz.

|

Part 4: Phase Detector

The phase detector is a flip-flop which is set

on the rising edge of the transmitter (camera)

sync pulse and cleared on the rising edge of the

receiver sync pulse.

If the two signals are exactly 180 degrees out of phase

(which is the condition we want, since the viewer lens is

separated from the camera lens by 180 degrees)

then the output  will be a square wave (i.e. it will

have a 50% duty cycle)

with an average value of 7.5 V.

If the receiver gets ahead of the camera (i.e. its sync pulse

comes too early) the wave form will be at 0 V longer than it

will be at 15 V and its average value will decrease.

Similarly, if the receiver gets behind the camera, the average

value of

will be a square wave (i.e. it will

have a 50% duty cycle)

with an average value of 7.5 V.

If the receiver gets ahead of the camera (i.e. its sync pulse

comes too early) the wave form will be at 0 V longer than it

will be at 15 V and its average value will decrease.

Similarly, if the receiver gets behind the camera, the average

value of  will increase.

Since both the loop filter and the motor summing amplifier

are inverting,

increasing

will increase.

Since both the loop filter and the motor summing amplifier

are inverting,

increasing  will increase the speed of the

receiver motor to catch up with the transmitter

and decreasing

will increase the speed of the

receiver motor to catch up with the transmitter

and decreasing  will allow it to fall back,

exactly the situation we want.

will allow it to fall back,

exactly the situation we want.

| |

|

|

Step 1: |

|

Get a 4013 CMOS flip-flop chip.

Its pins are numbered like this:

|

Step 2: |

|

Wire the phase detector circuit.

Be sure to connect power and ground.

|

Step 3: |

|

To prevent damage to the chip, connect the unused inputs

(pins 3, 4, 5, and 6) to ground.

|

Part 5: Loop Filter

Two things are wrong with the phase detector output:

Although the average value reflects the phase difference,

the signal itself is either +15 V or 0,

i.e. it needs to be smoothed.

Also, when the two signals are properly aligned

(180 degrees apart), this average value is 7.5 V.

But our motor driver circuit is designed so that when the

motor is running at the proper speed, the correction voltage is

zero,

i.e. we need to shift the signal by -7.5 V.

If we make the amount of shift variable, then we can control the

amount of offset between the camera and receiver disks.

Then we will have a position control to center the received image.

| |

|

|

Step 1: |

|

Wire the loop filter circuit:

|

Step 2: |

|

Connect  from the phase detector output to the loop filter input.

Don't connect

from the phase detector output to the loop filter input.

Don't connect  to the motor driver yet.

to the motor driver yet.

|

Step 3: |

|

Turn on the power

And adjust the position control potentiometer to

-7.5 V.

|